Menu

Menu

- Concord Products

- All Truck Equipment

- Accessories

- Airport Equipment

- Asphalt Maintenance

- Bodies, Dumping

- Bodies, Platform

- Bodies, Service

- Controls

- Electrical Components

- Hoists

- Hydraulics

- Ice Control

- Leaf Collection

- Lighting

- Plow Equipment

- Plows, Front

- Plows, Underbody

- Plows, Wing

- Power Brooms

- Service Equipment

- Snow Plow Hitches

- Spreaders

- SWEEPERS

- Wear Parts

- Wood Chip Collection

- Custom Manufacturing

- Parts & Service

- Gallery

- Around The Shop

- Resources

- About Us

- Careers

- Contact Us

Job Description

Concord Road Equipment Mfg., LLC is an Equal Opportunity Employer. The Company is registered with the Federal NHTSA as an Intermediate and Final Stage Manufacturer of Incomplete Commercial Truck Chassis. Along with a competitive pay structure, the Company provides benefits including but not limited to medical, disability, and life insurance; matching profit sharing; paid vacation and holidays, uniforms and more. Current work schedule is 7:00 AM to 4:30 PM Monday-Friday.

Position Summary

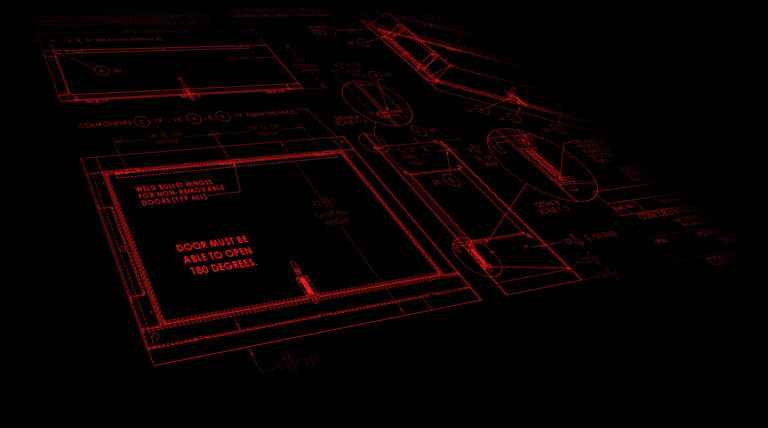

Under general supervision, is responsible for the design and development of ideas and concepts into technical diagrams or drawings for the manufacturing of machinery and mechanical devices and the installation of components and systems onto mobile vehicles, including dimensions, fastening methods, and processes of operation with the use of computer-assisted design software.

Responsibilities (additional related duties may be assigned as required)

- Create robust 3D models of complex sheet metal & structural steel components with information from customers and senior management utilizing SolidWorks. Should be familiar with advanced sheet metal and weldments modeling tools.

- Generate, maintain, and/or modify layouts, drawings, bills of materials, part models, part assemblies, and specifications for manufacturing and production personnel.

- Produce CNC program files using Hypertherm ProNest and Cincinnati Bend Simulation software packages. (CAD/CAM software)

- Generate and update manufacturing work order and job documentation and instructions for production and customers.

- Design and illustrate basic electrical wiring harnesses and hydraulic schematics for use in product manuals.

- Generate and print operational information and/or warning labels for company manufactured products.

- Compute mathematical formulas relative to detailed drawings or specifications for components, machinery, or systems.

- Aid and direct production workers in the application of designs and processes.

- Use relevant information and individual judgment to determine whether events or processes comply with applicable laws, regulations, or industry standards.

- Create reference manuals or technical publications to describe operation and maintenance of products or systems.

- Organize and perform work in a timely manner at a pace that ensures production schedules are satisfied.

- Comply with directives, methods, policies, procedures, or protocols established by Company management.

Work Environment

- Fast paced and project focused environment with ongoing primary projects and short-term task interruptions.

- Shop environment will expose the employee to dirt, dust, grease, chemicals, sparks, heat and loud noises.

- Sporadic outside work will expose the employee to adverse weather conditions which may require the ability to tolerate extremes in temperature and weather conditions.

- Use of hands and arms for the handling, positioning, moving and manipulating of objects.

- Working in close proximity of computers, equipment, power tools and machinery will require normal vision and hearing accuracy or any deficiency correctable to within normal ranges.

Necessary Knowledge, Skills and Abilities

- Proficient with the use of SolidWorks and AutoCAD / DraftSight modeling software

- Familiarity with mechanical manufacturing processes and equipment

- Preferred knowledge of 12-volt electrical and hydraulic systems

- Ability to read and interpret engineered drawings, documents, and specifications

- Capability to develop and design detailed drawings using computer-assisted software

- Ability to analyze and design technical solutions that satisfy customer and/or company goals

- Proficient with the use of Microsoft Office 365 software suite

- Ability to use calipers, tape measures, micrometers, protractors, and angle finders

- Capability to coordinate the activities of multiple projects simultaneously and prioritize, schedule, and accomplish projects efficiently

- Ability to communicate information and ideas through oral and written expression so others will understand designs, concepts, and ideas

- Ability to understand and carry out verbal and written instructions

- Ability to develop and maintain effective working relationships with associates

- Ability to lead, influence, and inspire others by personal example

- Employee may be required to perform the duties of a different classification

Qualifications

- Requires an Associate Degree or equivalent in mechanical engineering or relevant engineering field (Bachelors preferred)

- Requires minimum of three years mechanical engineering and product design

- Preferred three years of mechanical design and layouts including implementing product changes

- Proficient with computer-assisted design CAD software i.e., SolidWorks, AutoCAD / DraftSight, etc.

- Proficient with Office Suite software

- Preferred knowledge of Hypertherm ProNest, Cincinnati Bend Simulation, and Brady-ID labeling software